High Quality

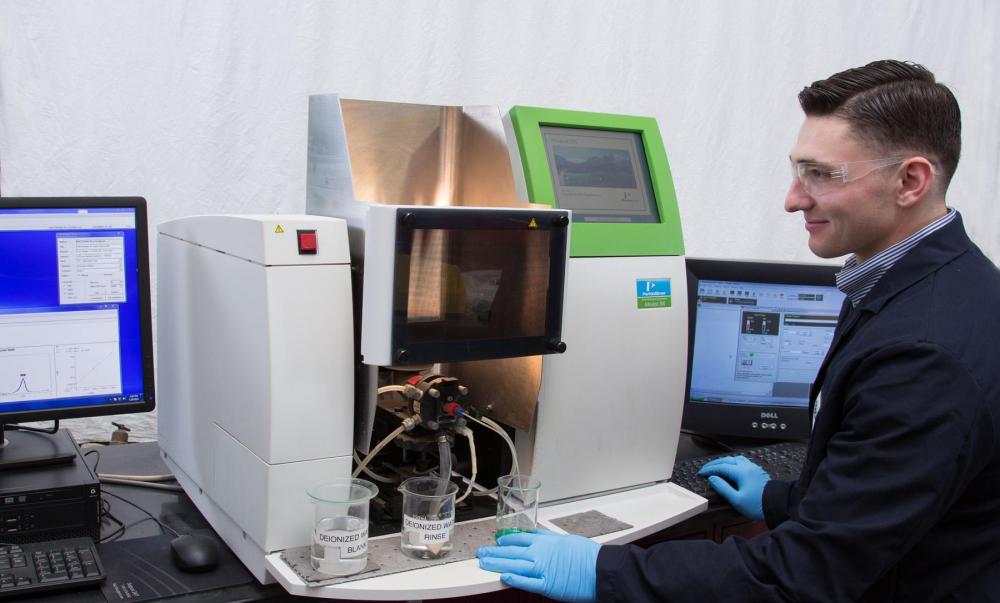

Thanks to the staff of highly educated and experienced engineers, Greystone Poland design and manufacture non-standard equipment and processes. This enables us to achieve high precision selective plating (galvanizing) with a thickness of several microns, on different areas of one part. In order to ensure that shipment of products free from defects, Greystone Poland has the possibility of 100% control of critical surface characteristics and dimensions. All this makes the coatings offered by us meets even the most demanding applications where safety is important.

Greystone Poland Certifications

Our customers (OEM, Tier 1, Tier 2) consistently control our plant, helping us to maintain and adapt to their requirements the high-quality accredited Greystone production system. Key parts in terms of safety, fit well with our high-quality certificates, which we have at the production plant in Stalowa Wola.

- ISO 9001

- IATF 16949

Greystone Poland Environmental Policy

Greystone Poland focuses on achieving environmental compliance through activities aimed at: environmental protection, protection of natural resources, recycling, waste reduction. We continually improve of our systems in order to provide a safe and sustainable workplace and community for our employees and neighbors. Greystone’s facilities have received numerous awards from local governing authorities for environmental excellence.

- Reduced manufacturing carbon footprint

- Significant waste reduction due to efficiencies & improved quality

- Plating (electroplating, galvanizing) process meets the environmental regulations – the cycle of chemical compounds is closed and fully controlled

- Reduce part handling – reduced to minimum chance of contact chemical compound with PPS™ machine operator

Greystone’s modern Precision Plating Process® (PPS®) allows the safe use of hexavalent chromium (hard chrome) – which is unique on Global scale. We designed the electroplating (plating) technology which minimized the impact on the environment.