Electroplating is a very popular and widely used process, as it increases the lifetime, reliability and functionality of parts made of metal (e.g. stainless steel, aluminum, etc.). This is due to the fact that the electrochemical process produces permanent, metallic coatings with a thickness measured in microns. These can be layers of chromium, zinc, nickel, as well as other coatings, depending on their properties that are required in the final products.

Until recently, in the electroplating process, an employee was responsible both for manual masking of areas that should not be covered in the electrochemical process, as well as for the transport of parts between different stages of production. Greystone has developed the Precision Plating System® (PPS®) which is fully automated and allows for selective electroplating of parts. The operator (employee) is only to supervise the process – the rest is pre-programmed.

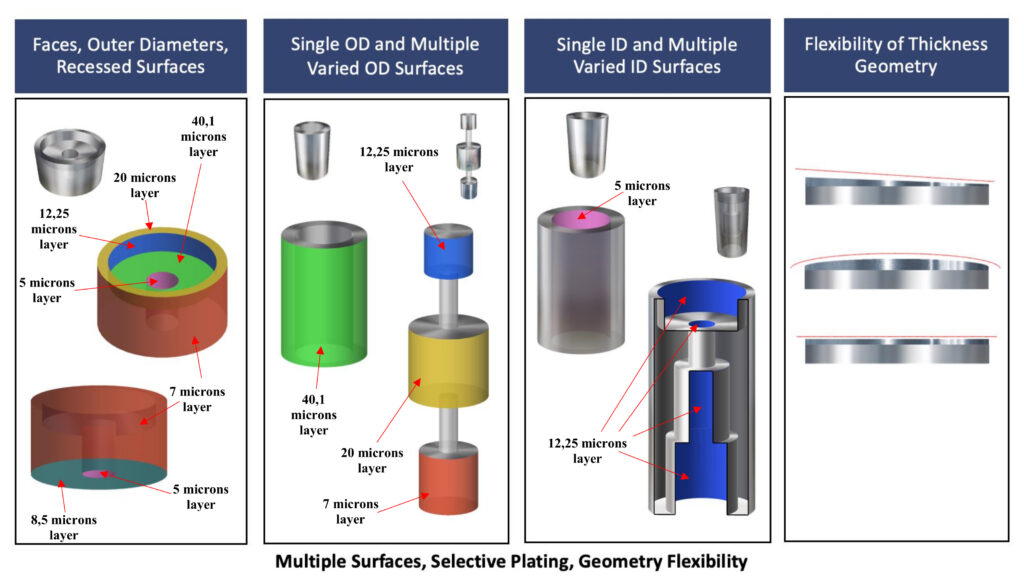

Thanks to this, it became possible to selectively plate parts – at select areas (on the part) on which a specific thickness of a given coating is to be applied, e.g. hard chrome. All this is illustrated in the graphics below.

If you have any questions please contact us

We are open to cooperate with so please contact with us. We will describe you our plating (galvanizing) process in more detailed way and help you to improve your product.

Mobile: +48 698-178-648

E-mail: pkrzyszkowski @greyst.com