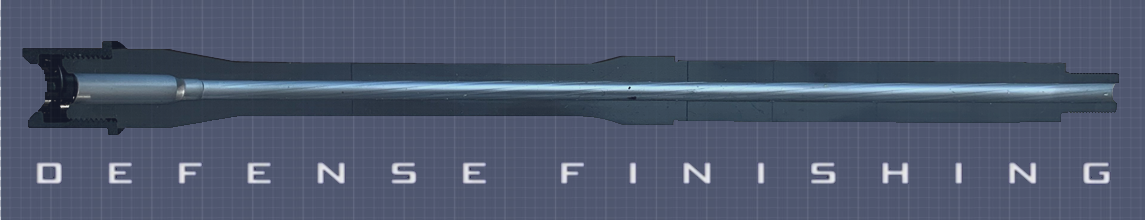

We are pleased to announce that Greystone Poland will be present at the IWA Outdoor Classics (World’s Leading Trade Fair) which will be held in Nuremberg (Germany) from February 29 to March 3, 2024. It will be our pleasure to meet with you and present all the advantages offered by our gun barrel chrome plating (lining) services.

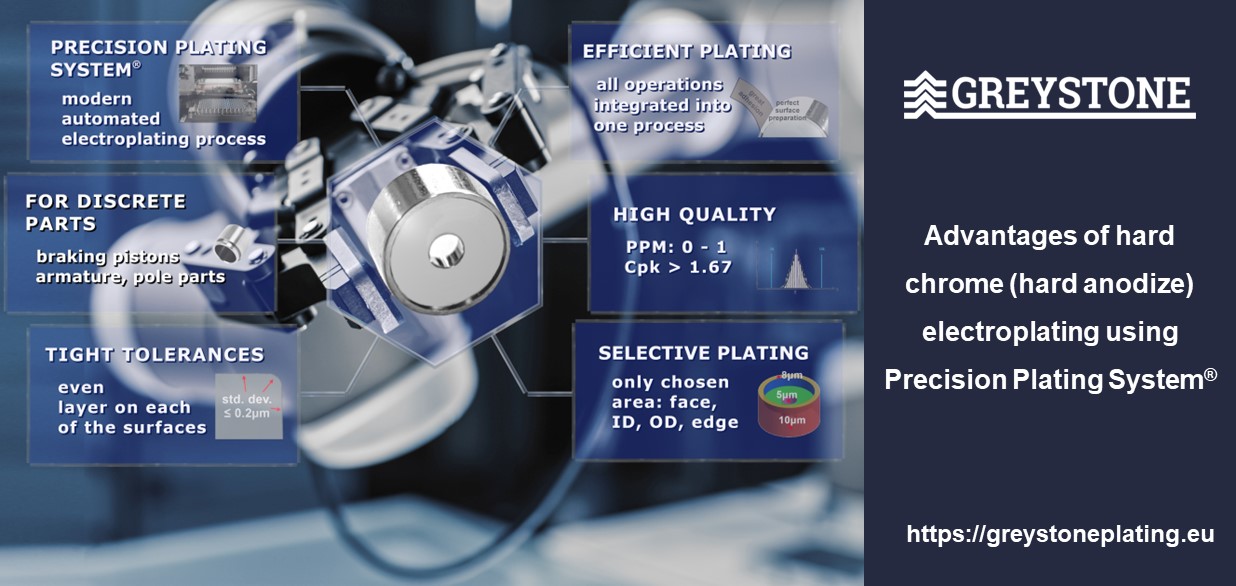

The technology was developed and improved in the United States for the needs of the military and civilian markets there and will soon be available in Europe.

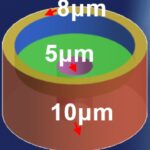

Thanks to Greystone’s industry-leading technical advancements with electroplating, a precisely controlled deposit of chrome is applied with uniform thickness, throughout the entire length of the barrel and also on the muzzle crown. Greystone’s proprietary processing technology yields preferred muzzle geometry to provide functional performance of Chrome Lining without negatively affecting accuracy. By meeting the minimum chrome thickness requirement on all internal surfaces of the barrel, maximum endurance is achieved even under severe shooting conditions such as sustained high rates of fire, and even with full-auto fire applications.

Please contact us and arrange a meeting, we will be more than happy to answer all your questions.

If you have any questions please contact us

We are open to cooperate with so please contact with us. We will describe you our plating (galvanizing) process in more detailed way and help you to improve your product.

Mobile: +48 698-178-648

E-mail: pkrzyszkowski @greyst.com