Coatings

Greystone Poland is constantly developing innovative engineering solutions for precision galvanizing services. Our production, technological capabilities, knowledge and experience could be adjusted to serve your needs of high-volume plating. Greystone Poland has ability to develop a new electroplating technology (machines and chemicals) in accordance with the customer’s requirements.

Hard Chrome (engineered chrome or industrial chrome)

Hard Chrome is one of the most popular functional coatings where the wear resistant is the most important parameter. Greystone has the knowledge and the ability to achieve tight tolerances of the layer thickness covering the metal part.

- Improves durability.

- Increases hardness of the part.

- Better corrosion protection of the part.

- Increases the wear (and abrasion) resistance of parts.

- Reduces friction between working parts - lubricity.

- Creates smooth surface that is easier to clean.

- Prevents seizing & galling.

- Good heat resistant.

- Extends the life cycle of critical parts which affects the extend of life cycle of a component > part > device > machine.

The STERIChrome™ coating reduces bacterial adherence allowing for easier cleaning and decontamination. This is especially true when applied over welded areas and other irregularities that are subject to become easily contaminated. Extensive research has proven the coating’s results to exceed the ISO 10993 standard requirements when tested for Hypersensitivity, Reactivity and Systemic Toxicity.

(Nodular) Thin Dense Chrome (TDC / NTDC)

Thin Dense Chrome (TDC) / Nodular Thin Dense Chrome (NTDC) is a type of Hard Chrome coating with all the advantages previously described and with denser structure. In addition, the deposit is not a micro-cracked (enhanced corrosion resistance). Thanks that on sharp corners and edges build-up and nodulization its reduced. Typical thickness range is from 0,508µm (0.00002″) to 12,700µm (0.0005″).

Hard (coat) Anodize

Hard (coat) Anodize is an electrochemical process that forms a non-conductive anodic oxide layer on the surface of an aluminum or other non-ferrous metal. Thanks that the superior coating is achieved, thanks which the durability of part is gained into another high level.

- Increased Corrosion Resistance.

- Superior Wear Resistance.

- Higher abrasion resistant (gliding properties).

- More durable (high-strength bond).

- Higher surface hardness.

- Non-conductive - dielectric barrier.

- Aesthetics - parts look better.

- Sterilized, non-contaminating attributes.

Zinck-Nickel

Zink-Nickel coating has high performance corrosion protection and it is used on parts where exceptional protection against external conditions is required. Can achieve 240+ hours to first white corrosion and 960+ hours to first red corrosion. This layer is using very often by automotive industry especially for parts used in harsh environments. Zinc-Nickel layer will corrode slower than Zinc layer.

- High performance corrosion protection.

- Limits thermal stress to parts subjected to higher operating temperatures.

- Reduces friction.

- Limits opportunities for abrasion.

- Better wear resistance - compared to conventional zinc.

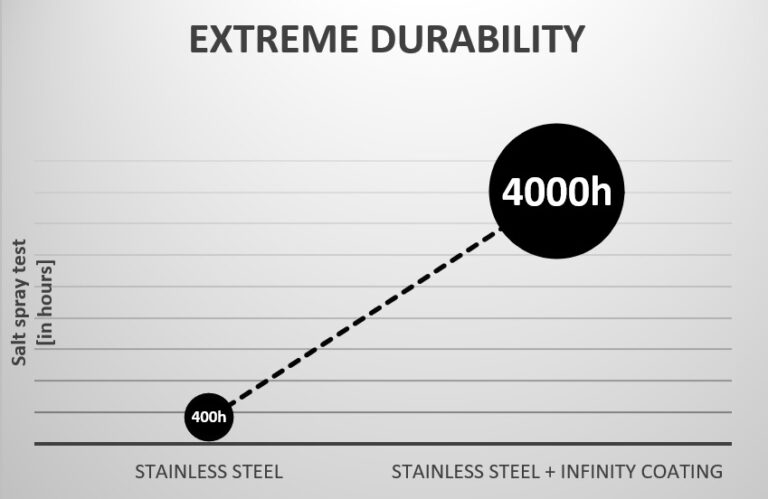

Infinity™

Infinity™ is a Nickel type coating used on parts with tough/extreme usage. We think that it gives the best anti corrosion protections for parts where it is essential. It is Greystone proprietary plating technology.

- The Infinity™ coating brings the advantages of Zinc-Nickel coating to the highest level.

- Can last extreme salt spray test: till 4000h (stainless steel last only 400h depending on type).

- For applications where parts are exposed to extreme corrosive conditions, like in maritime market.

- Eliminates rust and other rusty stains.

- Looks shiny like silver layer.

According to customers’ needs and requirements Greystone offers other Nickel type coatings such as: Electroless Nickel and Electrolytic Nickel.

Silver

Silver coating is widly used in electrical / electronics industry. It is idealy layer for different kind of electrical connectors. Using this layer causes that product will have very high electrical conductivity. It also has the lowest weight of precious metals.

- Exeptional electrical conductivity

- Improves the solderability of the substrate.

- Biocompatible and antimicrobial, antibacterial.

- Exceptional lubricity even at high temperatures.

- Resistant for corrosion.

- Resistant for oxidation.

- The highest light reflectivity of any other metal.

- Appearance - looks shiny.