Plating Technology

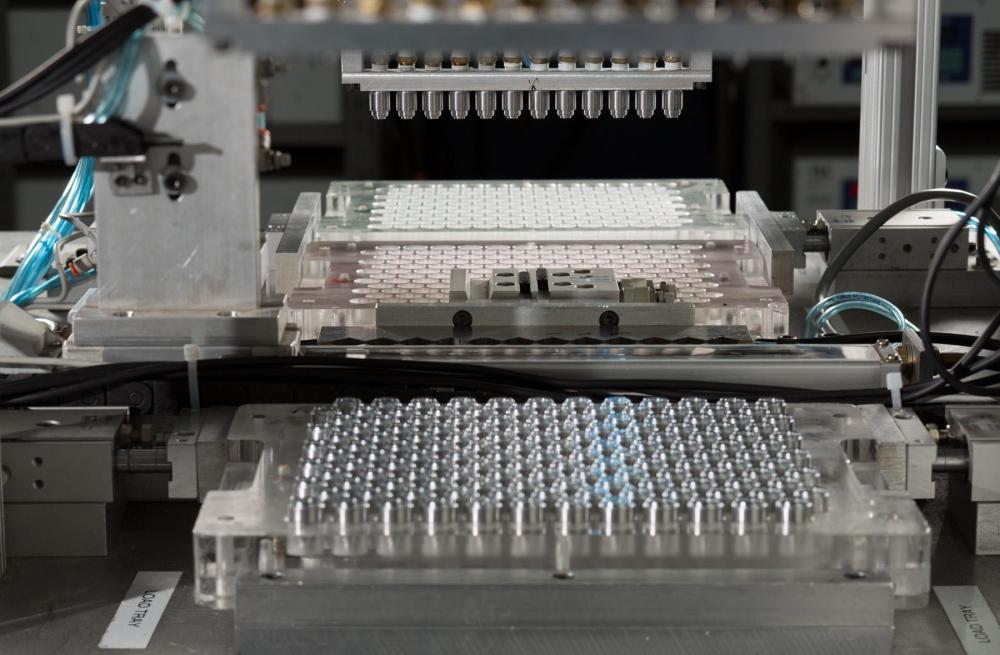

Greystone introduces to the world the most modern and environmentally friendly electroplating technology. In recent years, we have developed a highly efficient high-volume system for precise, selective coating (electroplating) of small (discreet) parts. Plating takes place without human contact and complies with environmental regulations. We call this groundbreaking new technology: Precision Plating System® (PPS®).

Precision Plating System®

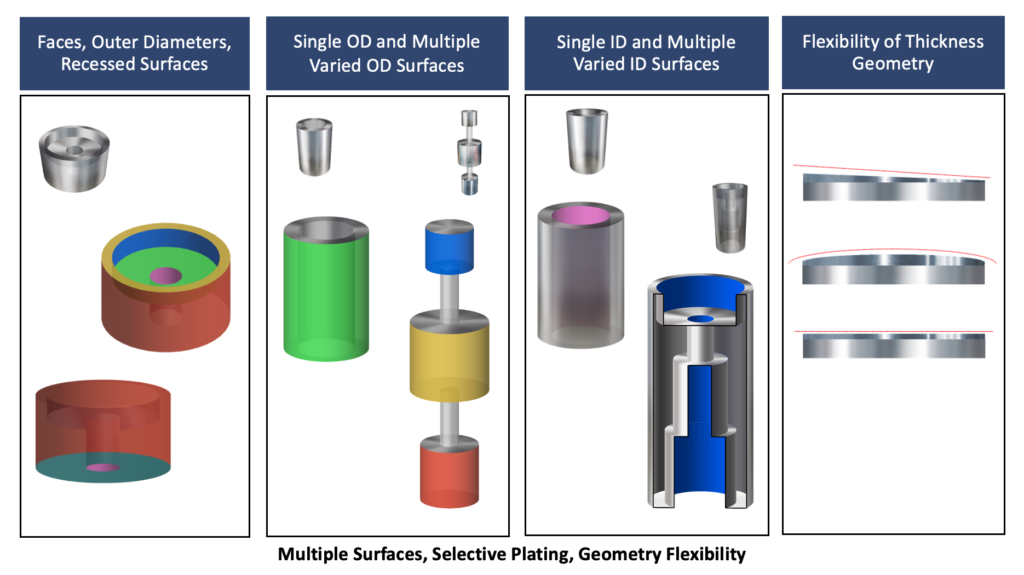

The modern and unique PPS® system enables engineers to adapt electroplating technologies to their specific requirements (applications). The Precision Plating System® gives you the freedom and flexibility to coat many selected areas: exactly where you want them with exact thicknesses – all within one tight tolerance process.

Each PPS® can be independently adapted to individual requirements according to the developed new techniques and electrochemical coatings. The Precision Plating System® has an automated production line that integrates high quality and eliminates inconsistencies in the application of masking and anode alignment. This is achieved by automatically placing each part in the designed tooling with individual monitoring and position adjustment. Thanks to the PPS® system, Greystone Poland can precisely monitor and track the electroplating process of every single part (even out of a million processed). If there occurs any inconsistencies in our control parameters, PPS® will automatically quarantine the suspect product (set it aside).

Thanks to the continuous improvements provided for almost 90 years, high work culture and innovations, the dedicated Greystone Automation Department constantly designs and builds custom electroplating applications – in accordance with the requirements of customers.

Universal plating applications

Our world-class production system – PPS® developed for the automotive market (quality, production, audit) – has been adapted to the requirements and needs of our customers from other markets. including:

Environmentally friendly plating

Greystone’s Precision Plating Process® allows the safe use of hexavalent chromium (hard chrome). The impact on the environment is kept to a minimum [link to quality]. Thanks to this, there is no need to replace coatings composed of hexavalent chromium for environmental (ecological) reasons. It is worth to notice that hard chrome provides unparalleled performance compared to other coatings in highly engineered applications such as: Gears, Heatsinks, Spools, Solenoids, Sensors, Valves and Valve Seats, Pistons, Fuel Injectors.

Plating flexibility

The Precision Plating System® (PPS®) is state-of-the-art and can be easily adapted to the various electrochemical coating processes:

- Chrome (Hard Chrome)

- STERIChrome™ (medical usage)

- Anodize

- Nickel

- Silver

- Gold

- others – according to clients specification

PPS® Advantages

The Precision Plating System® allows us to coat multiple areas on one part in one process with the exact designed thickness and desired plating profile.

o Cpk > 1,67 for tolerances 10% of the nominal thickness

o St. Dev. in current production as low as ≤ 0.2µm