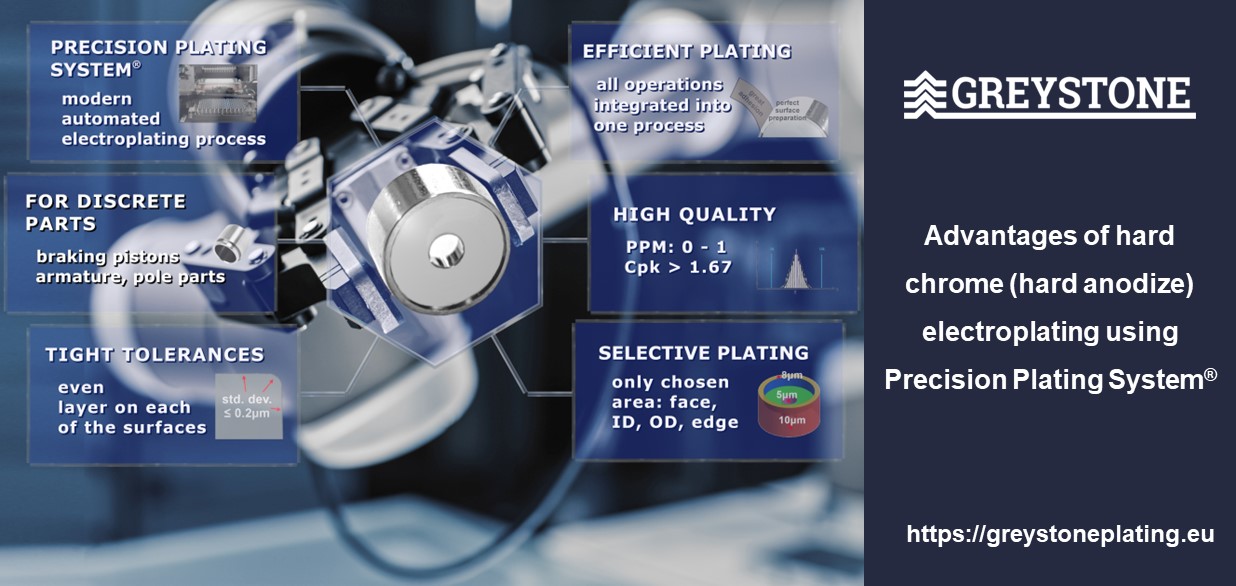

Basic advantages of hard chrome (hard anodize) electroplating using Greystone’s Precision Plating System®.

PPS® is state-to-art technology that is fully automated and uses a robotized system for manipulating the parts. Thanks that it is ideal to plate the discrete (small) parts like braking pistons and valve components for fuel systems (like armatures, poles type parts) and others.

All hard chrome (hard anodize) electroplating operations are integrated into one process. Thanks to that surfaces are perfectly prepared and we achieve great adhesion. As a result, high quality is obtained: Cpk>1.67 and PPM: 0 – 1.

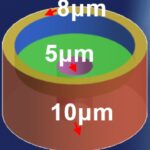

Precision Plating System® is modern and allows for selective plating of parts. Only chosen areas of the parts can be covered by a hard chrome (hard anodize) layer, like: face, ID, OD, edge. During that electroplating proces tight tolerances are achieved of each of the surfaces: std. dev. as low as ≤ 0.2µm

If you have any questions please contact us

We are open to cooperate with so please contact with us. We will describe you our plating (galvanizing) process in more detailed way and help you to improve your product.

Mobile: +48 698-178-648

E-mail: pkrzyszkowski @greyst.com