The described “actual process capability factor” – Cpk informs about the accuracy of manufacturing of a given part. This is a very important parameter, especially in mass or large-scale production which takes place at the Greystone Poland plant in Stalowa Wola. The higher the Cpk value, the lower the risk of producing a defective product. The worldwide standard of customer requirements for manufacturing companies is that the production process has a Cpk value> 1.33. With such a factor, the defectiveness of the manufactured parts is about 0.0063%.

Thanks to highly qualified employees and a modern production line, the plating process carried out in Greystone Poland in Stalowa Wola is very accurate and its: Cpk> 1.67. It is an added value that all our clients receive. Thanks to this, we minimize the resulting waste and costs, as well as obtain a final product of very high quality.

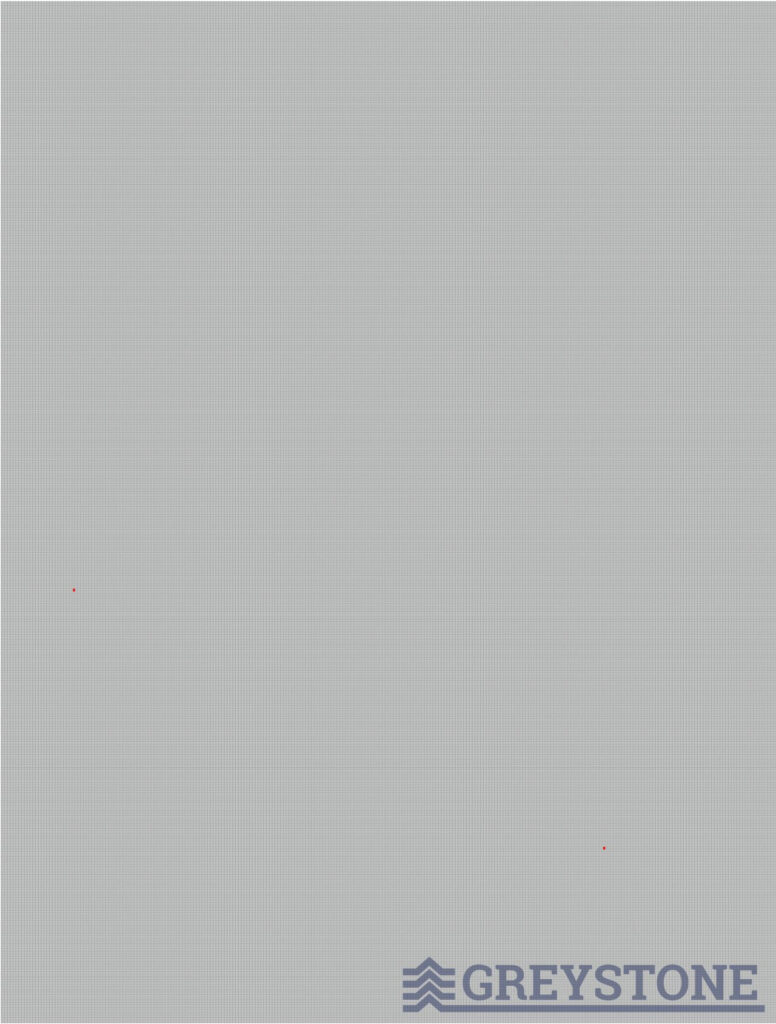

Typical PPM (Parts Per Million) in our factory is 0 – 1. Is it a lot or a little? Faulty parts (out of a 1 million produced) are marked in red in the attached photo.

If you have any questions please contact us

We are open to cooperate with so please contact with us. We will describe you our plating (galvanizing) process in more detailed way and help you to improve your product.

Mobile: +48 698-178-648

E-mail: pkrzyszkowski @greyst.com