Due to the fact, that Greystone Poland passed another certification audit conducted by TUV Nord Polska, a new tree was planted. It is a response to the challenges of the current world to take care of the nature around us. The action was organized by TUV Nord Poland. For every audit carried out, TUV Nord Poland committed to planting a new tree.

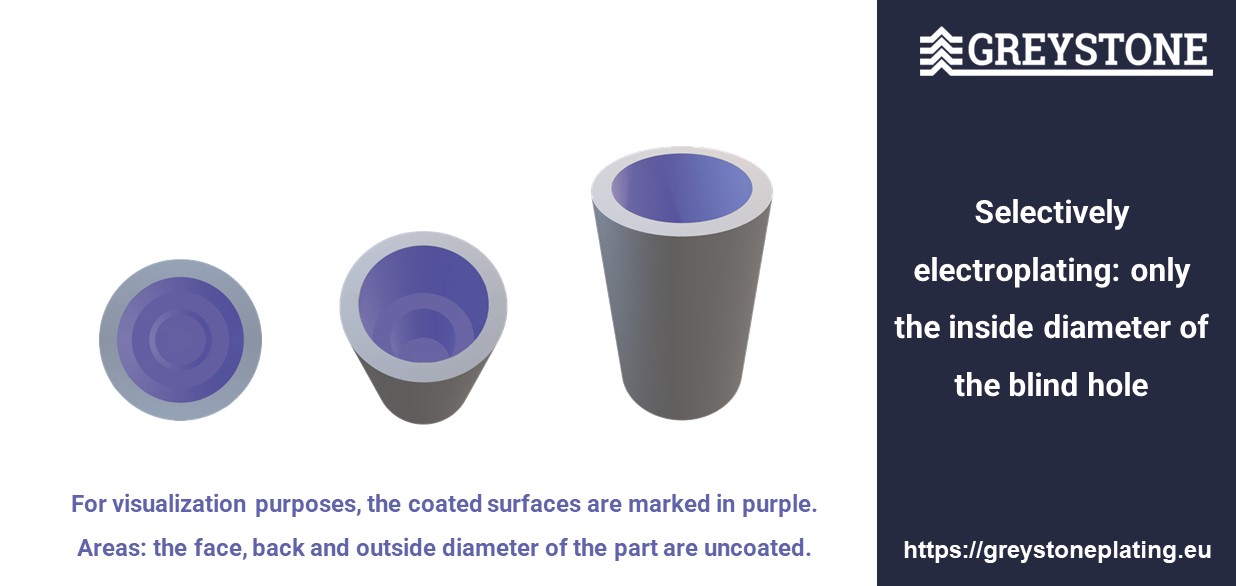

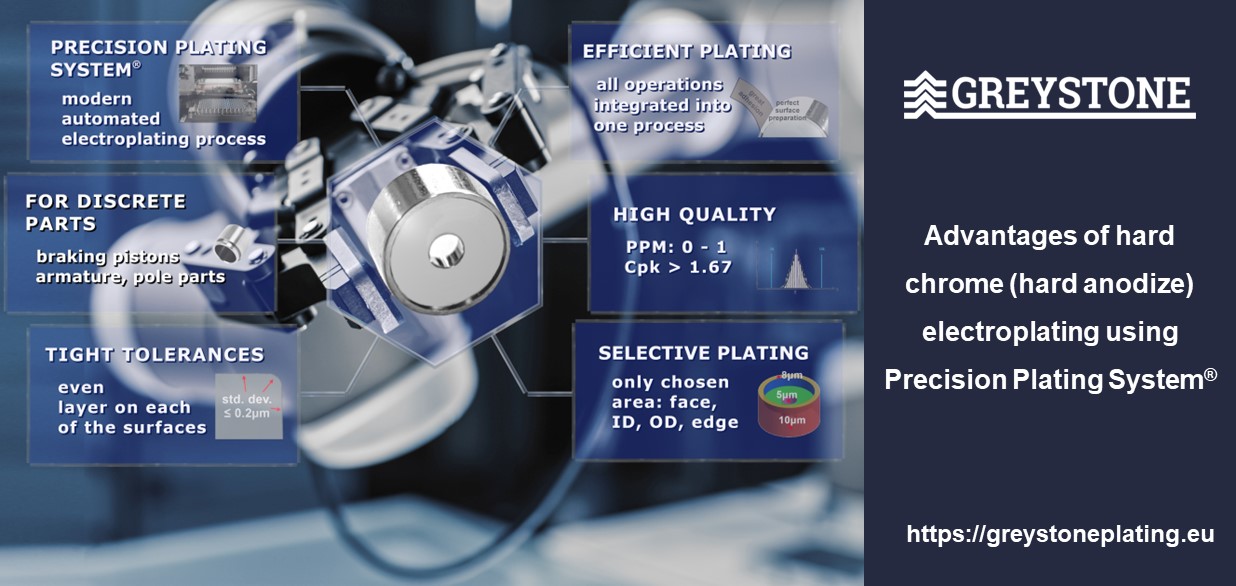

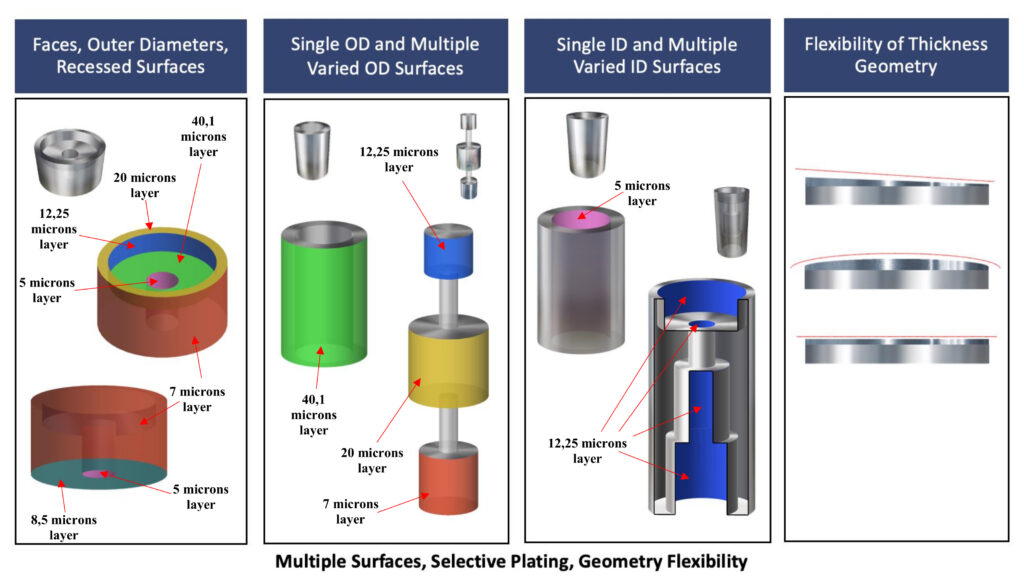

On this occasion, it should be noted that once again Greystone Poland has proven that the selective electroplating services offered are accompanied by high-quality standards. This was achieved thanks to the use of our unique Precision Plating System. PPS meets high standards set, among others: by the automotive industry. The plating system used by Greystone Poland is highly optimized thanks to a closed circuit, automation and meeting strict quality standards (PPM: 0 – 1) with high productivity (Cpk > 1.67).

If you have any questions please contact us

We are open to cooperate with so please contact with us. We will describe you our plating (galvanizing) process in more detailed way and help you to improve your product.

Mobile: +48 698-178-648

E-mail: pkrzyszkowski @greyst.com